At IC-Link, we understand the importance of flexibility. Whether you’re doing 50 pieces a year or 50 million, we know there is no one-size-fits-all approach for every project. It depends on a myriad of factors, from your company’s size and structure to its capabilities and the outcomes you need to deliver.

We are here to listen, to adapt to your needs, and to do what makes the most business sense for you and your organization. And at the end of the day, IC-Link has a solution for your application-specific integrated circuit (ASIC) that can be custom-tailored to your requirements.

Flexible business models that fit your needs

We help customers put together the entire integrated circuit, but that looks different from one organization to the next.

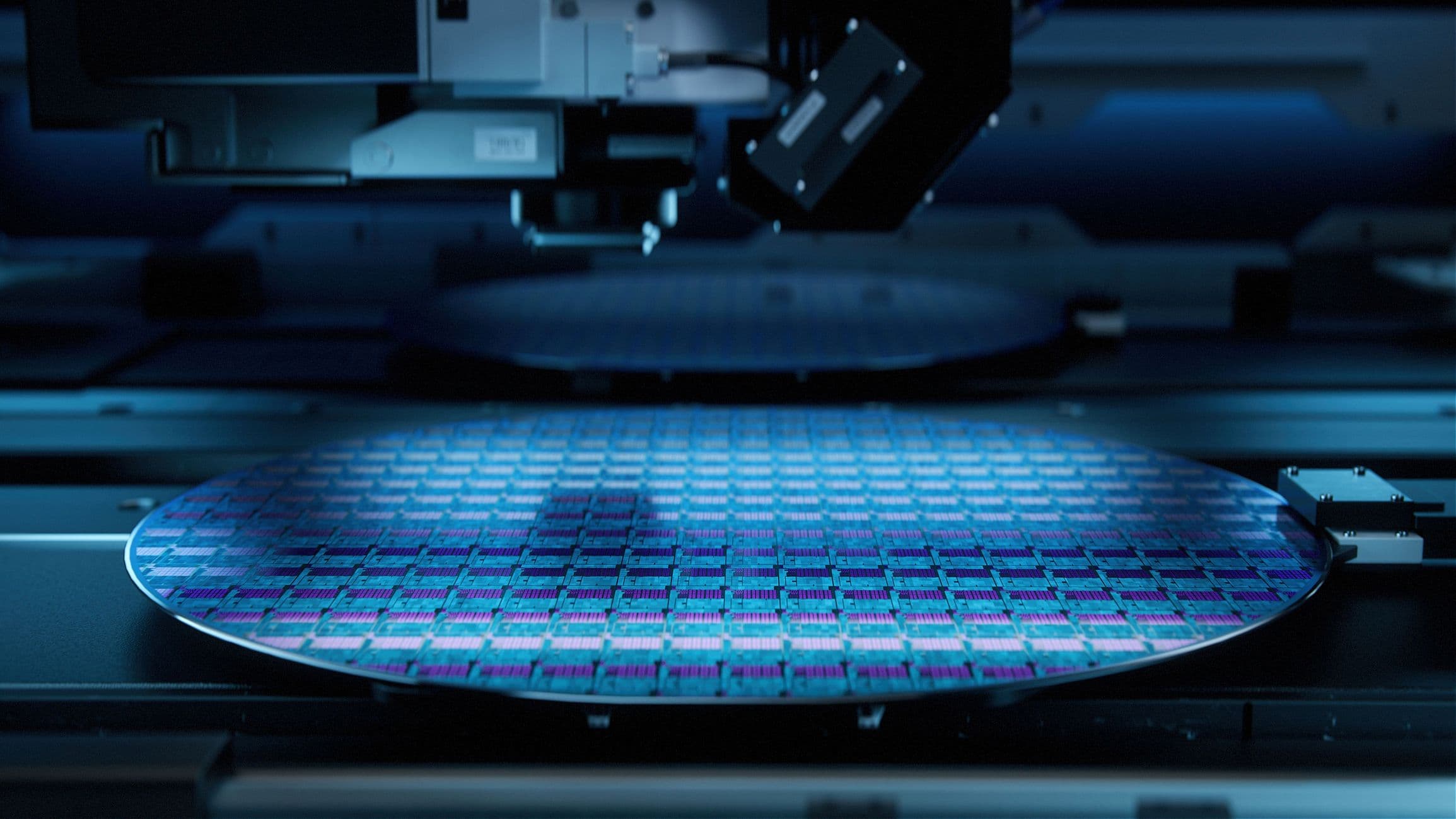

Some customers already have the in-house capabilities to accomplish many of the ASIC development processes themselves, including design, test, packaging, qualification and supply chain management. In these cases, IC-Link only supplies the wafers.

Other customers do not have the benefit of internal semiconductor expertise, but need a custom ASIC to implement key features within a product they’re building. Here, we manage the entire end-to-end process and deliver devices ready to be used in production.

We can also accommodate anything in between, depending on your specific requirements.

To most effectively address both use cases, IC-Link offers two flexible business models which can be customized to individual customer needs:

- Customer Owned Tooling (COT), which is low cost.

- Full TurnKey (FTK), which is low risk.

Selecting the right business model ultimately comes down to the capabilities you need from your custom ASIC, and finding a pricing structure that fits within your requirements.

What are COT and FTK, and which best suits your organization?

COT (Customer-Owned Tooling) is our most price-competitive model. We buy, test and package the wafers based on the customer’s own design. Customers are responsible for the ultimate yield, including any defects.

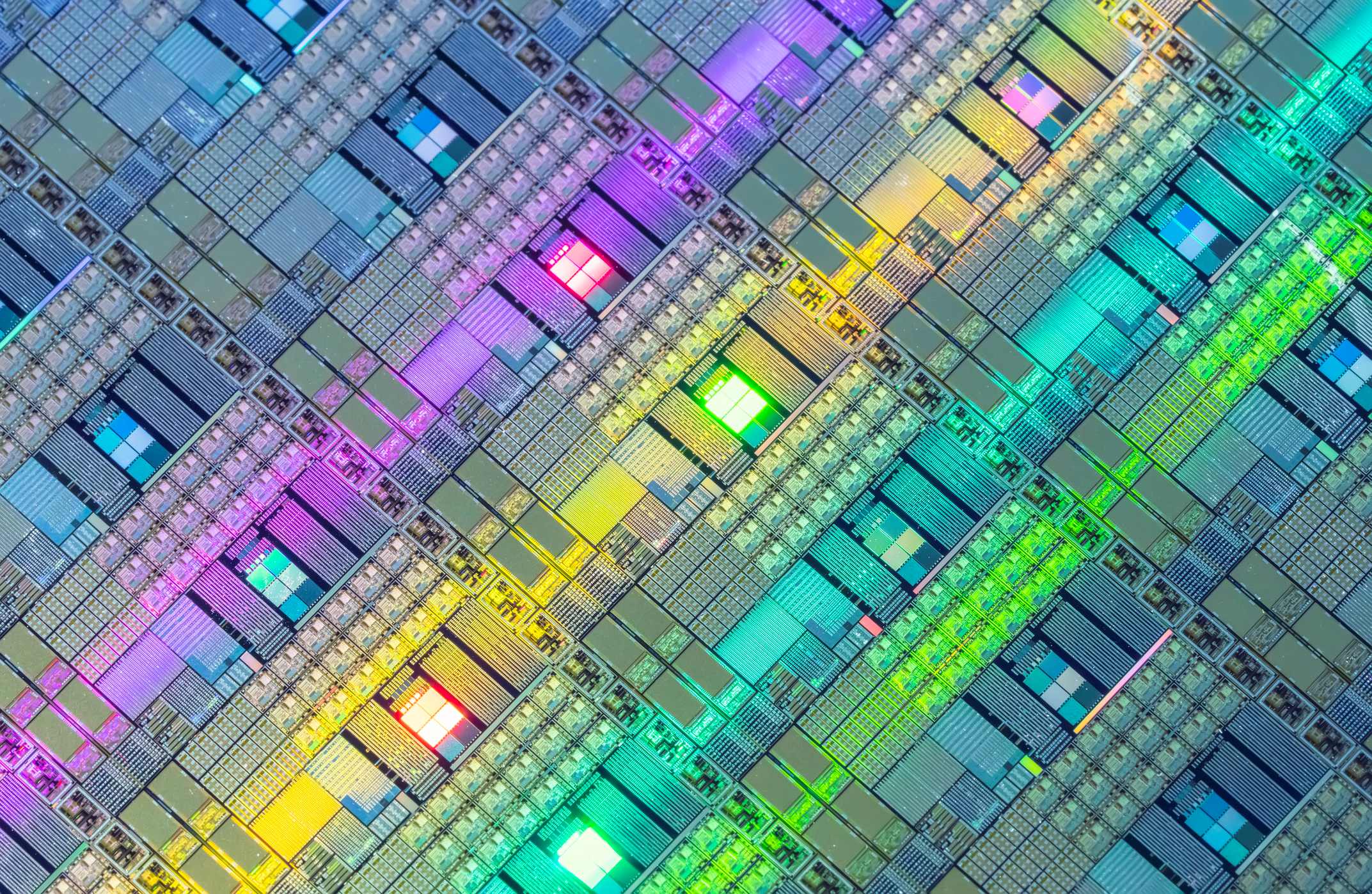

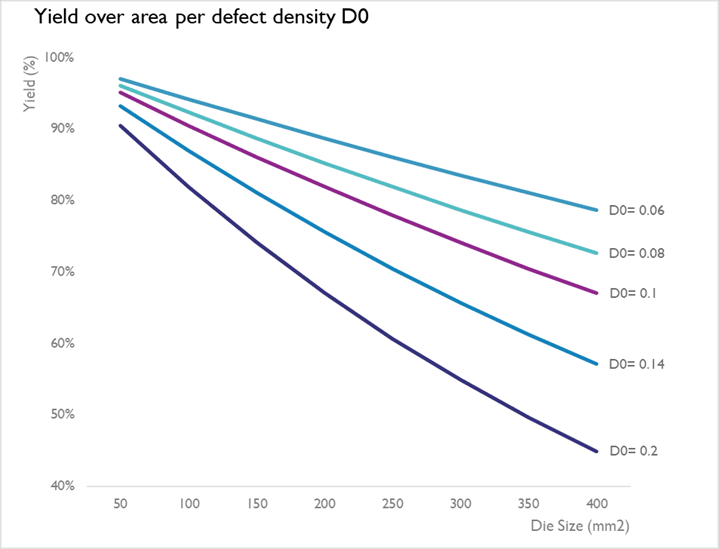

Average yield depends on a number of technical parameters, including die size and defect density (D0), but becomes easier to predict over time. Defect density tends to usually be lower for mature technology nodes compared to advanced nodes as processes become more predictable for nodes over time and volumes. As shown in the chart below, yield trends down as die size goes up. In the COT model, customers are guaranteed the entire lot for a single set price, but carry the risk of any defective chips.

This model is highly transparent and ideal for customers that bring internal expertise around the chip manufacturing process. Because the customer accepts the risk, COT represents the most cost-efficient model for customers that have a high degree of certainty around their design and yield. Other use cases include semiconductor companies that may be able to complete the design on their own, but need access to foundry and back-end services that only IC-Link can offer.

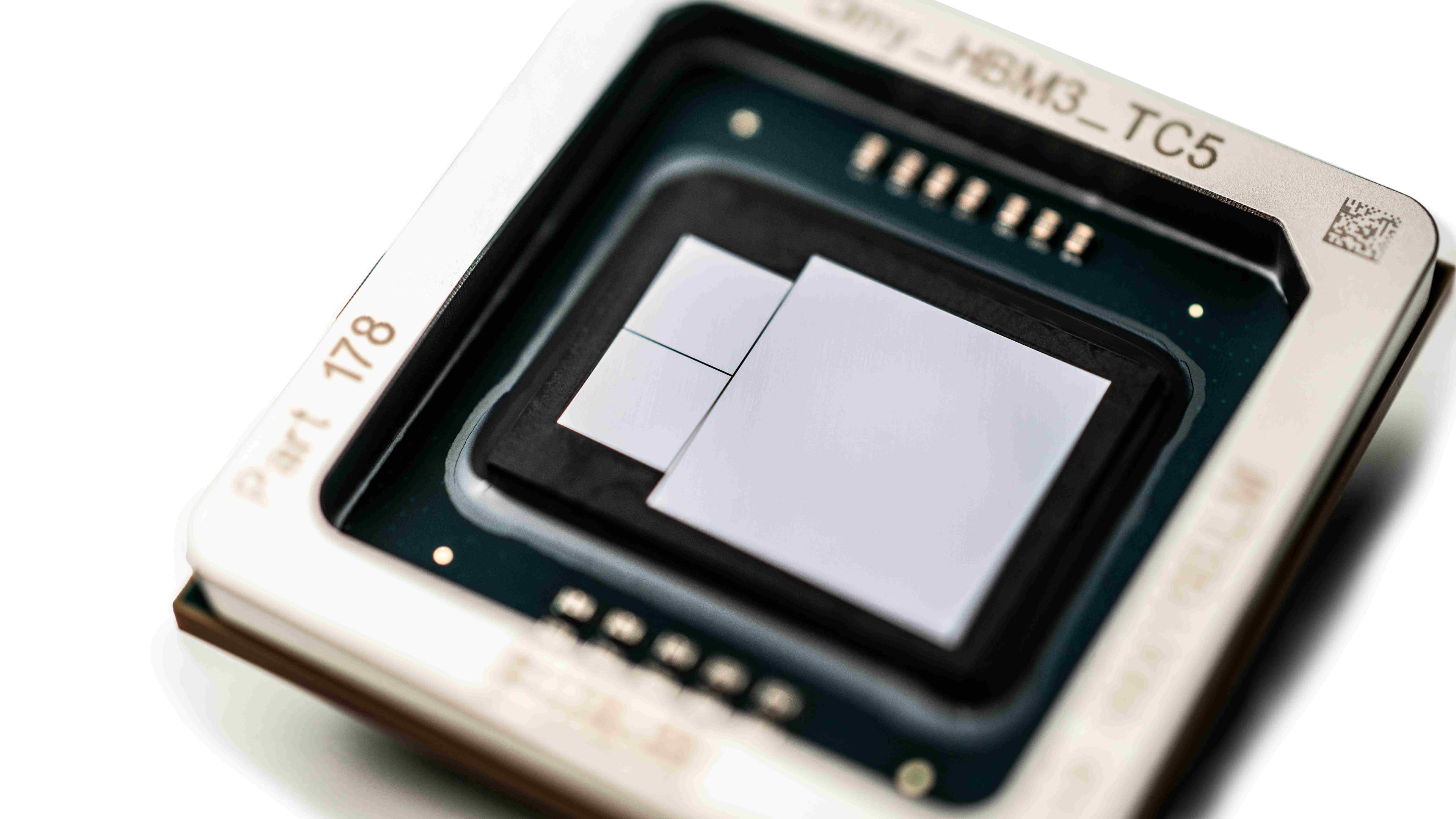

The FTK (Full Turnkey) model offers a fixed price per finished good, regardless of total yield. IC-Link accepts the risk for any defects, and delivers a set number of production-ready chips for a pre-established price.

This model is ideal for customers whose expertise is at the system level rather than around semiconductor design, manufacturing or test processes. It carries zero risk for the customer. At the end of the process, you have a guaranteed number of fully packaged chips that are ready to connect to your boards.

For example, if your company is making a product in the telecom or medical space, your internal expertise is in the product itself. You may need a custom ASIC to make that product run, but it’s simply a component – one that needs to be handed off to experts that can guarantee a working product. If you don’t want to give away your IP, but you need help on the back end – testing, qualification, and packaging – then the FTK model may be right for you.

Small batch or high-volume production, flexibility is our promise.

Our ultimate goal is to understand what you need and to make the appropriate recommendation and quote based on those needs. We can also hybridize the models to fit your needs over time by running test production loads to understand your average yield and make a longer-term agreement on a fixed price.

IC-Link handles all your production needs: from small batches up to projects that require more than 50 million pieces annually.

WithIC-Link, you will have a single point of contact all the way through development and the ability to pick and choose the offering that works best for your organization.

To learn more, or to set up an introductory call, get in touch.

Published on:

8 January 2025