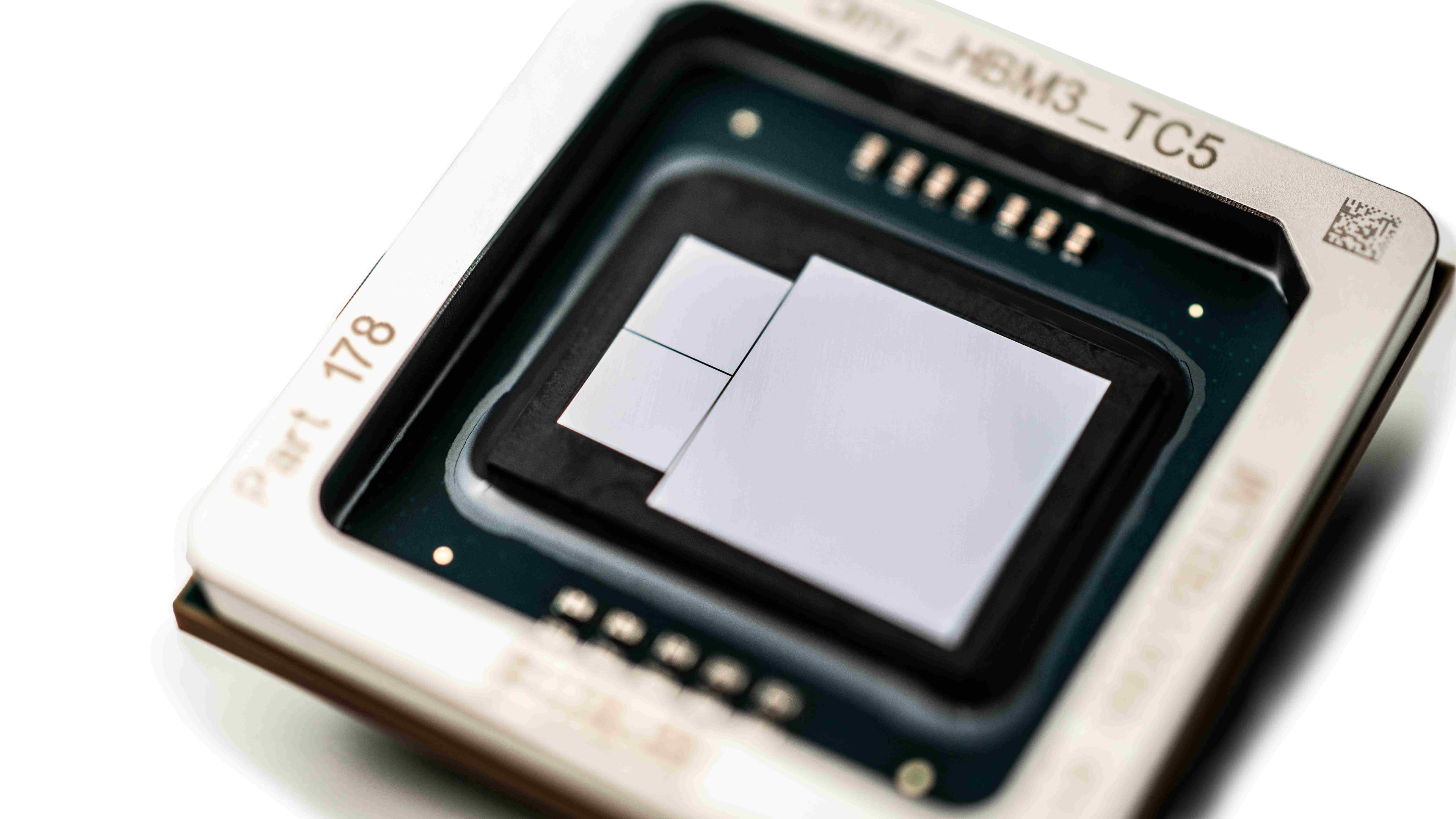

Off-the-shelf sensors work perfectly well for smartphone cameras. But a tool that must visualize structures at atomic-level resolution requires a highly customized sensor chip. That custom chip can only come from imec and IC-Link, says Olivier Rainaut, senior director of R&D for life science electron microscopy activities at Thermo Fisher Scientific.

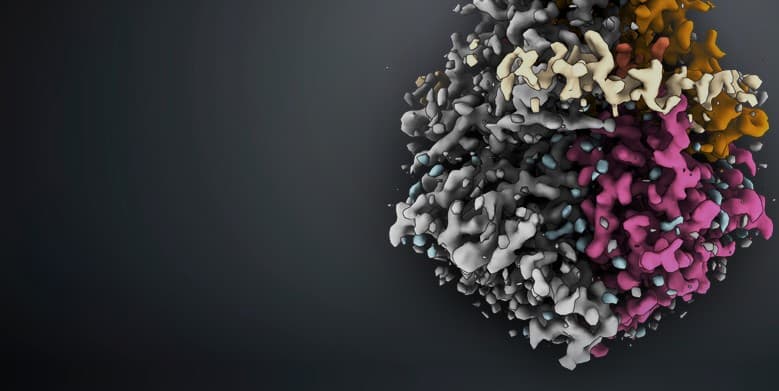

Electron microscopes don’t use light but electrons to visualize a sample. The sensor capturing these electrons must be extremely sensitive to allow the analysis of life-science images with exceptionally low contrast, such as tissues, membranes, and proteins.

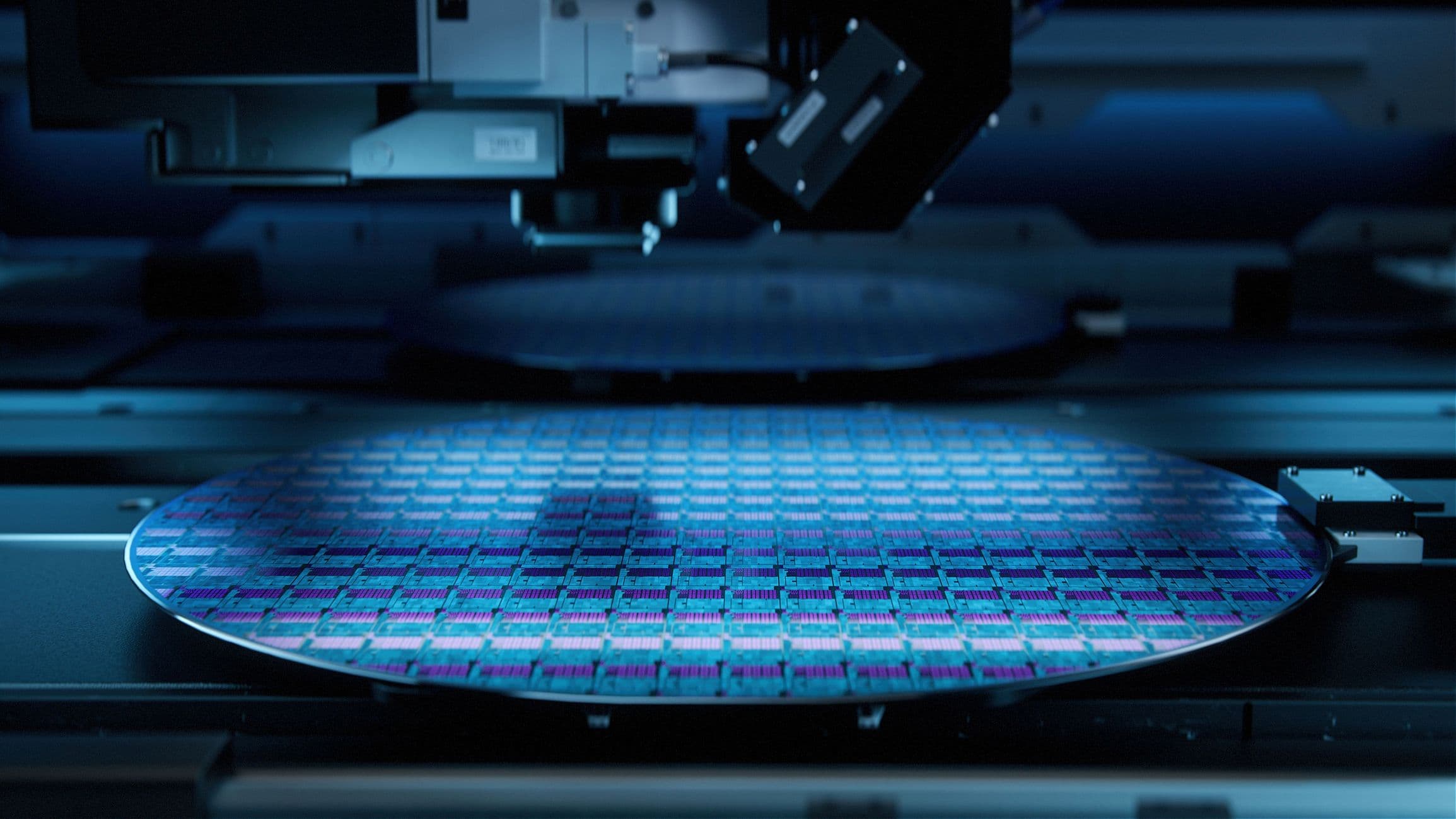

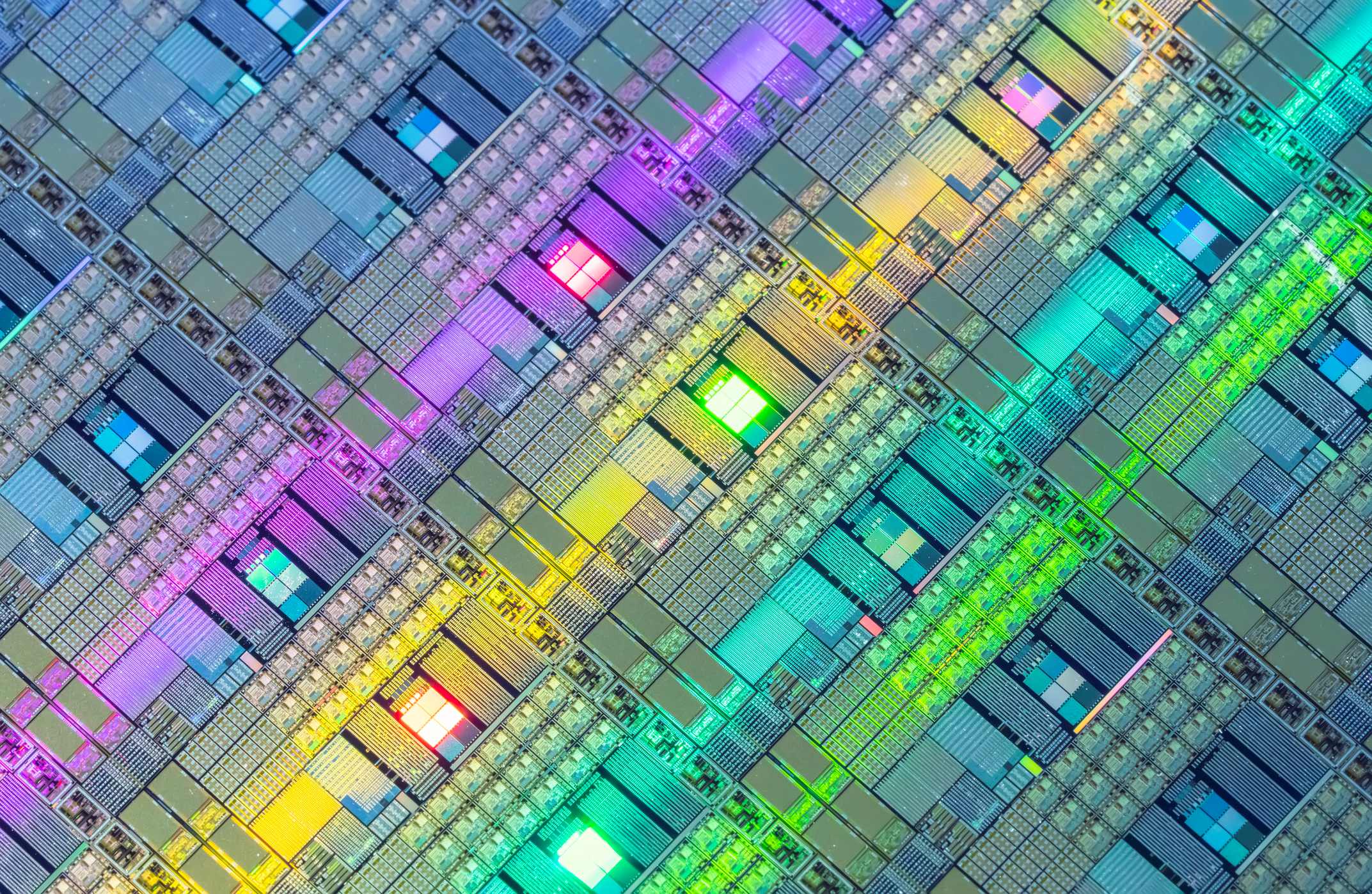

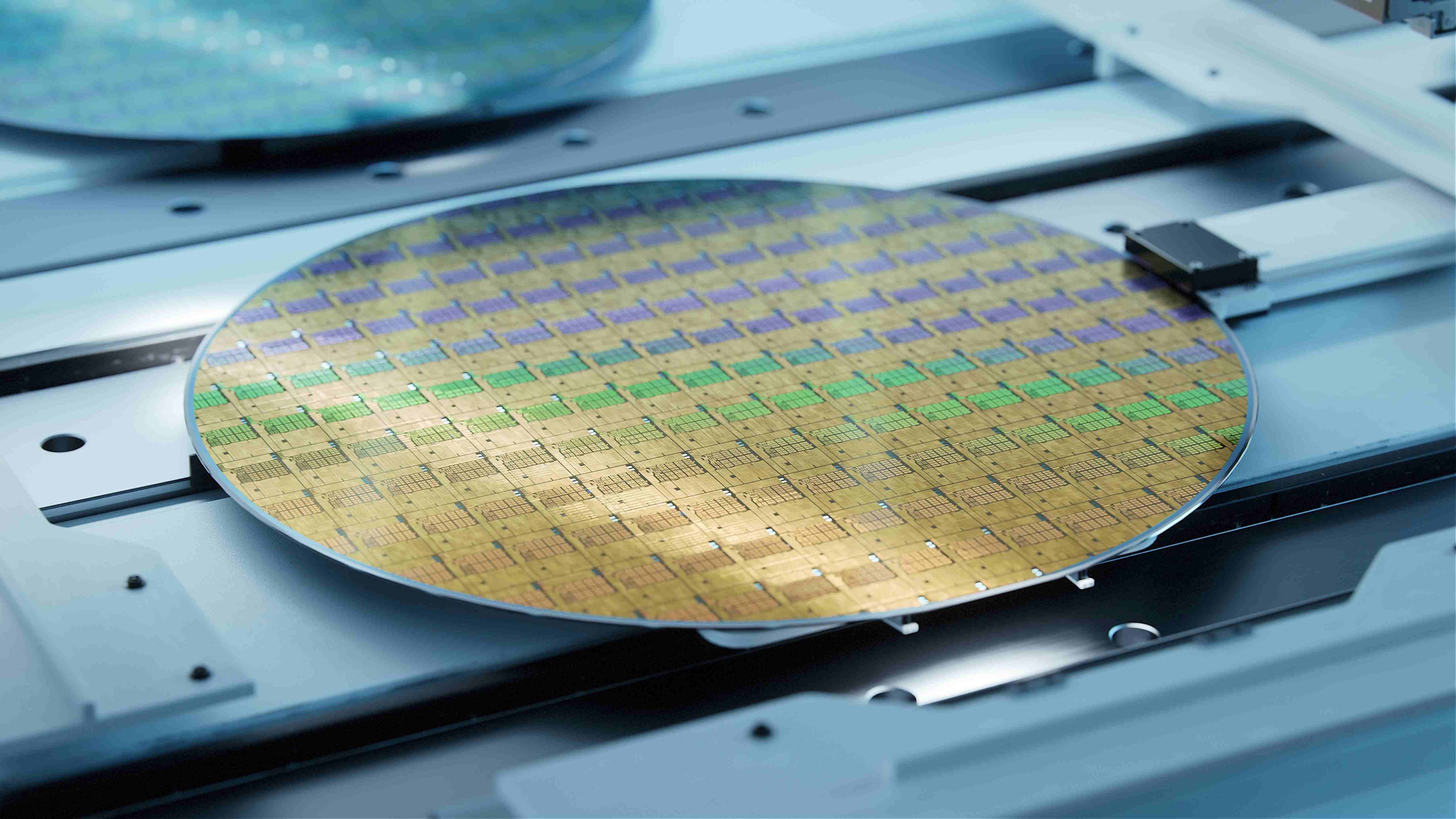

In addition, the remarkable size of the chip (5 × 5 cm, or 4 dies on one wafer) brings added challenges in terms of design, packaging, and dicing.

Thermo Fisher Scientific has been working on these custom sensors with imec (for the research) and IC-Link (for full development and manufacturing) for more than ten years. This collaboration has already resulted in four commercialized design iterations. New developments are on the way, while the production yield of existing products continues to be optimized.

For Olivier, the value of this long‑term collaboration lies in having guaranteed access to a partner capable of meeting the required specifications for design quality, volume, and yield.

Watch the video

Published on:

27 January 2026