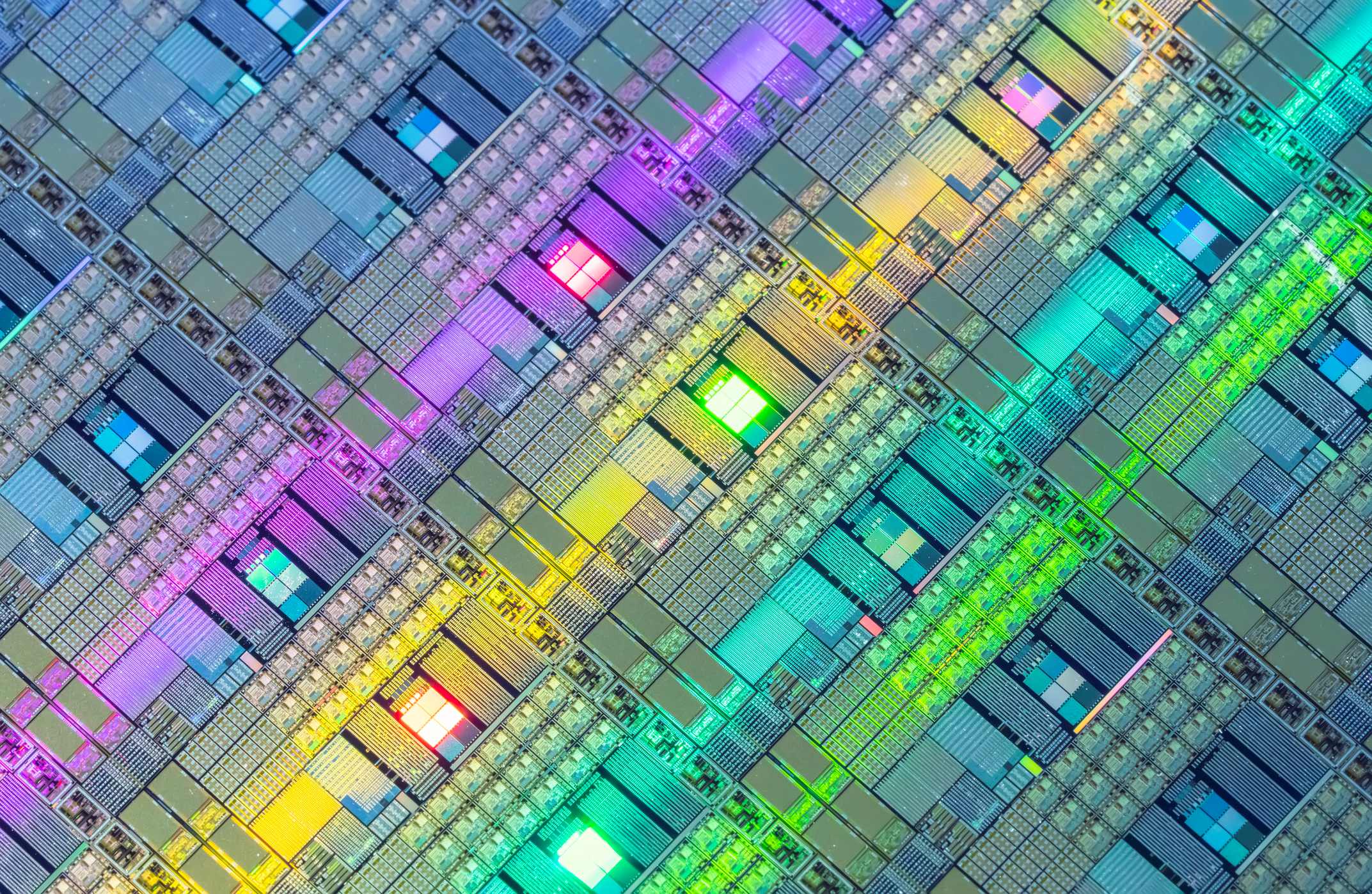

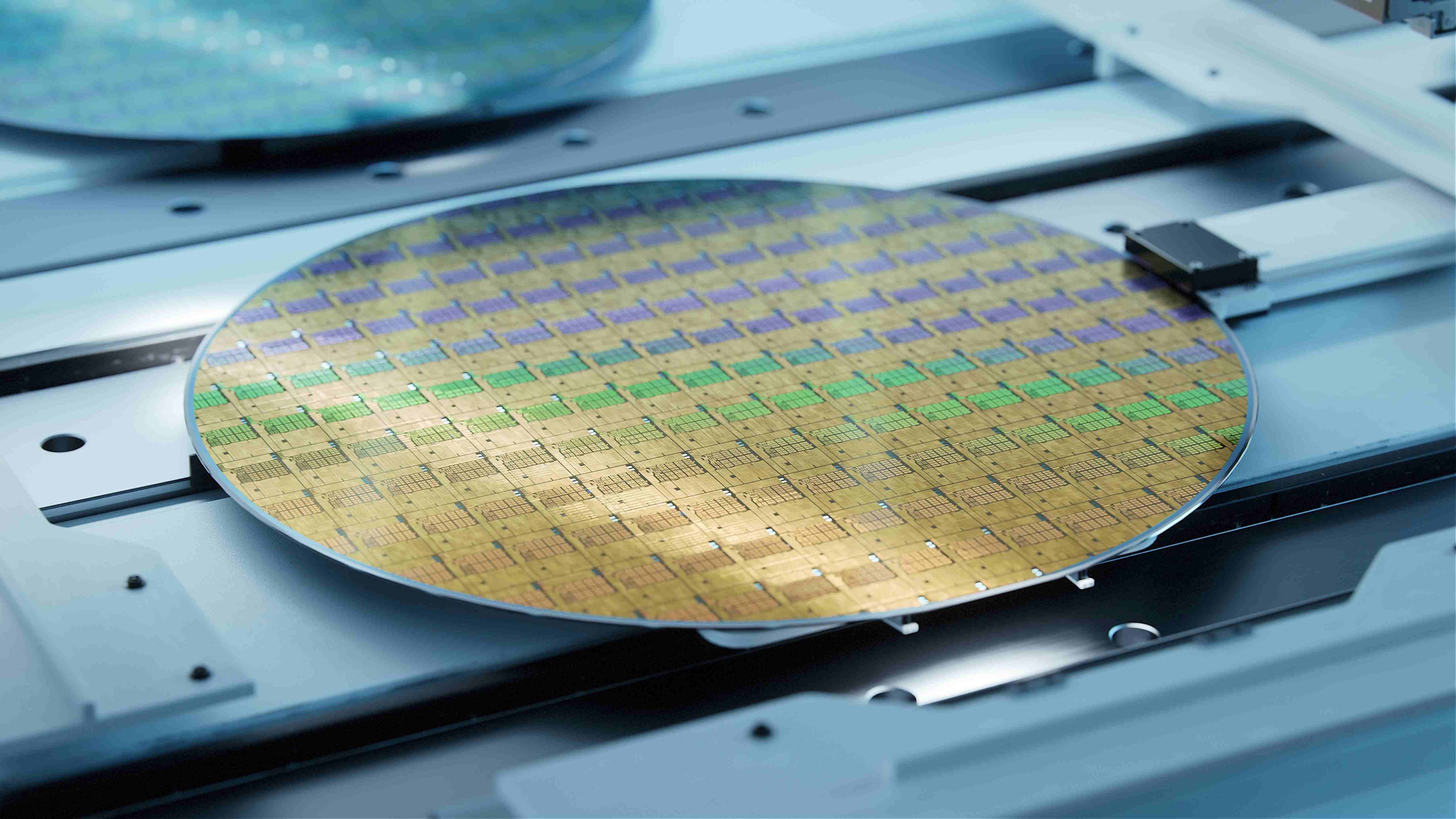

As a designer and manufacturer of automatic test equipment (ATE), Teradyne relies on custom ASICs to give their systems a competitive edge.

“Compared to off-the-shelf products, ASICs enhance the cost-effectiveness, features and performance of our final products,” says Andre Henderman, Teradyne’s senior director of silicon technology engineering.

But at what point does it actually make sense to invest in an ASIC? For Andre, building a solid business case starts from a basic formula:

“Total cost = development cost + unit cost × volume”

Because ASICs come with high development costs and low unit costs (compared to standard ICs), their use only makes sese if the expected volume is significant. Keeping both the development and unit costs under control is therefore key to a successful ASIC project. And that’s where IC-Link comes in.

“IC-Link helps us to manage the unit costs, so the ROI makes sense.”

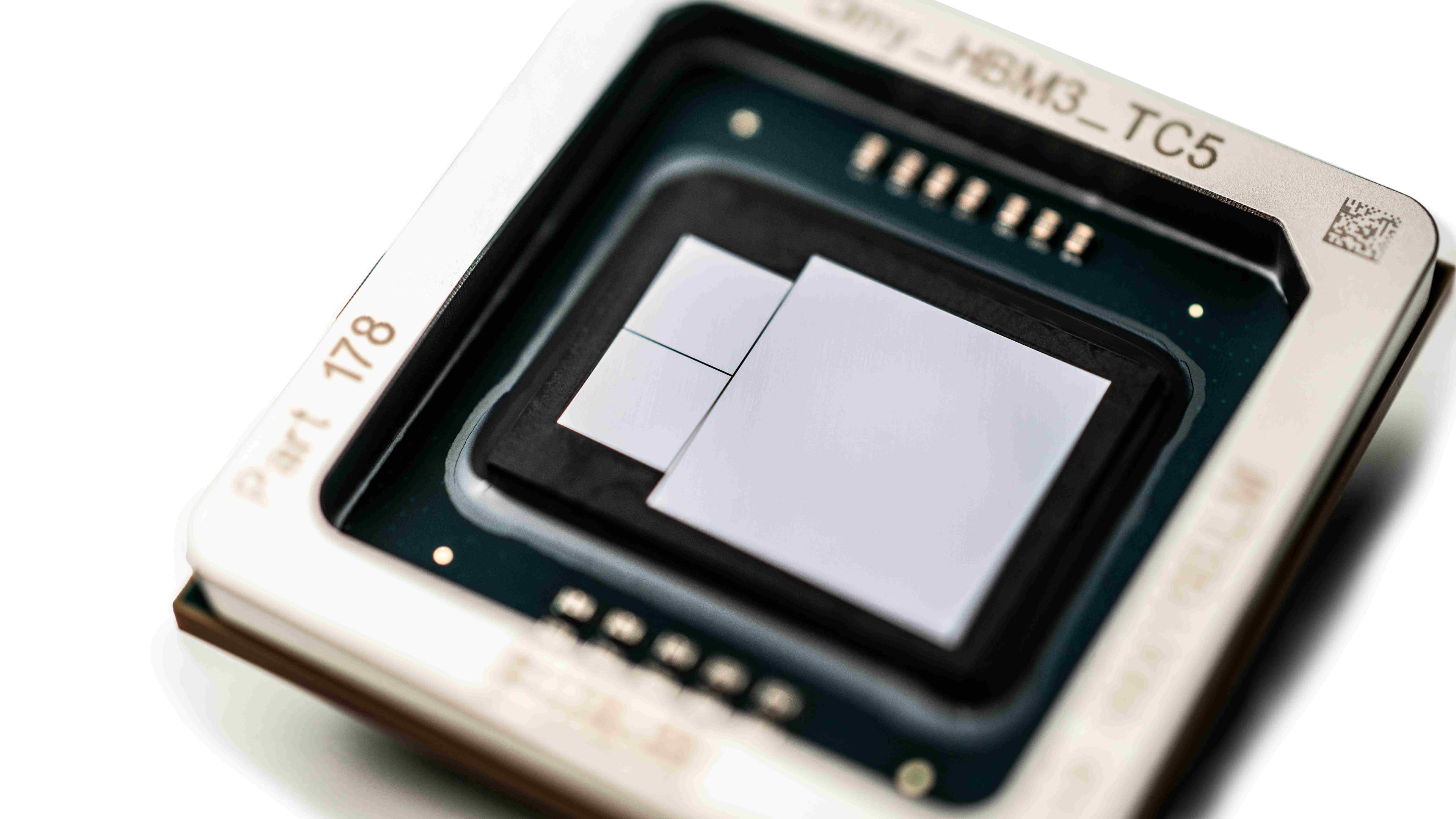

Teradyne has been working with IC-Link for more than eight years, and is looking to expand this collaboration in more of the ASIC development stages, such as physical design and package design.

This deeper collaboration is linked to the industry shifts Andre sees on the horizon: “The emerging chiplet ecosystem will create new challenges for ATE, as well as the solutions to those challenges – such as the chiplets used in the testing equipment.”

Watch the video

Published on:

27 January 2026